The construction industry has undergone significant transformations in recent years, and one of the most revolutionary changes has been the integration of robotics. Robotics in construction isn’t just a futuristic concept; it’s a reality that’s rapidly shaping the industry. These advanced technologies are being used in a variety of applications, offering numerous benefits that improve efficiency, safety, and overall project outcomes.

Applications of Construction with Robotics

- Drones for Site Surveying:

Unmanned aerial vehicles, commonly known as drones, have become invaluable tools for construction site surveying. They can capture high-resolution images and generate accurate 3D maps of construction sites. This data is crucial for assessing site conditions, monitoring progress, and making informed decisions throughout the construction process. - Automated Excavation and Demolition:

Robots equipped with advanced sensors and precision tools can perform excavation and demolition tasks with unparalleled accuracy. These machines can dig trenches, remove debris, and even work in hazardous environments that may be unsafe for humans. - 3D Printing for Construction:

3D printing technology is revolutionizing the construction of buildings. Large-scale 3D printers can create entire walls and structural components using a variety of construction materials. This not only speeds up the building process but also reduces material waste. - Robotic Bricklayers:

Robots capable of laying bricks and other building materials are increasing productivity on construction sites. These robots work with precision and consistency, reducing the margin for error and ensuring that structures are built to exact specifications. - Robotic Inspections:

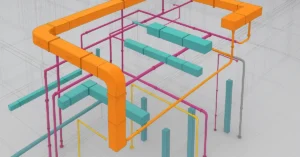

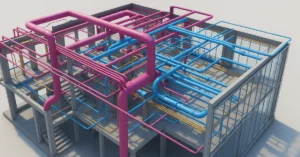

Drones and ground-based robots are used for inspections. They can identify structural defects, monitor the quality of work, and assess the safety of a site, all while reducing the risk to human inspectors. - Prefabrication and Assembly:

Robotic systems are used in prefabrication facilities to assemble components of a building, such as wall panels and roof trusses. This off-site construction method minimizes waste and accelerates on-site assembly. - Robotic Loaders and Heavy Equipment:

Autonomous loaders and heavy equipment are becoming increasingly common on construction sites. These machines can perform repetitive, labor-intensive tasks, such as moving materials and transporting loads, without the need for human operators. - Drones for Site Security: Drones equipped with cameras and AI algorithms enhance site security by monitoring for unauthorized access and potential safety hazards. They can also be used to deter theft and vandalism.

Benefits of Robotics in Construction

- Improved Safety:

Robotics can handle dangerous and physically demanding tasks, reducing the risk of accidents and injuries to human workers. This is particularly significant in construction, where safety is a top priority. - Increased Efficiency:

Robots work consistently and efficiently, 24/7, without fatigue or breaks. This results in shorter project timelines, reduced labor costs, and improved project profitability. - Higher Precision and Quality:

Robotic systems can perform tasks with incredible precision, ensuring that buildings are constructed to exact specifications. This reduces rework and improves the overall quality of construction projects. - Cost Savings:

While the initial investment in robotics may be significant, the long-term cost savings in terms of labor, time, and materials often outweigh the upfront expenses. It’s a strategic investment that pays off over time. - Environmental Benefits:

Robotics can help reduce construction-related waste and energy consumption. For instance, 3D printing produces less material waste, and autonomous machinery can optimize energy use. - Remote Operation:

Some robotics can be operated remotely, reducing the need for workers to be physically present on-site. This capability has proven especially valuable during times when on-site presence is limited, such as the COVID-19 pandemic. - Flexibility:

Many robotic systems are adaptable and can be reprogrammed to perform various tasks. This flexibility allows construction companies to utilize their robotics for multiple purposes, enhancing their return on investment.

Challenges and Future Prospects

While the use of robotics in construction offers numerous benefits, it also presents challenges. The upfront cost of acquiring and implementing robotics can be high, and there may be resistance to change within the industry. Additionally, the need for skilled workers to operate and maintain these machines is crucial.

Looking ahead, robotics in construction is likely to continue evolving. As technology becomes more affordable and accessible, smaller construction companies will be able to adopt these innovations. There will also be advancements in AI and automation, enabling robots to take on even more complex tasks, such as project management and decision-making.

Conclusion

In conclusion, the integration of robotics in construction is a game-changer for the industry. It offers a wide range of applications and benefits, from enhanced safety and efficiency to cost savings and environmental advantages. As the technology continues to advance, the construction sector is poised for a more innovative and productive future, improving the way we build our world.

If you’re interested in learning more about architecture firms in Europe, check out this comprehensive list of the top 50 firms compiled by Archgyan. From innovative startups to long-established industry leaders, this list has it all. Take a look and discover some of the most inspiring and influential architecture firms in Europe today.

If you’re interested in architecture and want to learn more about this amazing field, subscribe to our podcast on youtube

For more SketchUp tutorials, head to https://www.sketchupguru.com